Optimizing the stability of pharmaceutical products involves a comprehensive approach to ensure the product retains its quality, potency, and safety throughout its shelf life. Here are key strategies:

Formulation Development

1. Select stable excipients and APIs.

2. Optimize pH, ionic strength, and solvent composition.

3. Use appropriate buffers and preservatives.

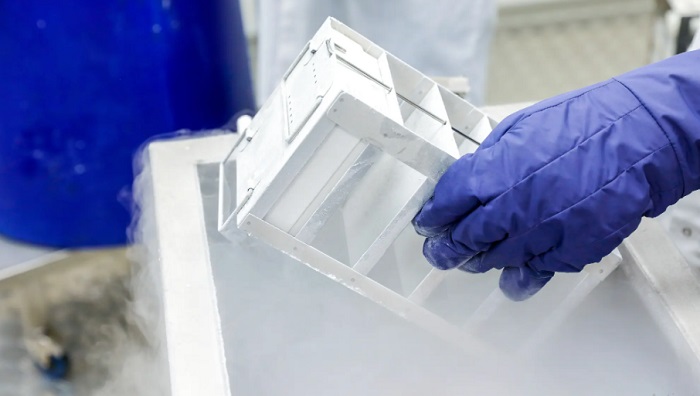

4. Consider freeze-drying or lyophilization.

Packaging

1. Choose suitable container materials (e.g., glass, plastic).

2. Ensure tight sealing and closure systems.

3. Use protective coatings or liners.

4. Consider nitrogen or argon flushing.

Storage Conditions

1. Control temperature (e.g., 2-8°C, 20-25°C).

2. Maintain humidity levels (e.g., 50-60% RH).

3. Protect from light (e.g., amber glass).

4. Store in a clean, dry environment.

Manufacturing Process

1. Validate manufacturing processes.

2. Monitor and control processing conditions.

3. Minimize exposure to heat, moisture, and light.

4. Implement Good Manufacturing Practices (GMP).

Stability Testing

1. Conduct accelerated stability testing (AST).

2. Perform real-time stability testing.

3. Evaluate stability under various conditions (e.g., temperature, humidity).

4. Monitor product degradation pathways.

Quality Control

1. Regularly inspect products for visible defects.

2. Conduct chemical and physical testing.

3. Monitor product potency and purity.

4. Implement a robust quality control program.

Supply Chain Management

1. Control transportation conditions.

2. Monitor storage conditions.

3. Ensure proper handling and distribution.

4. Implement track-and-trace systems.

Regulatory Compliance

1. Adhere to ICH (International Council for Harmonisation) guidelines.

2. Comply with FDA, EMA, or other regulatory agency requirements.

3. Maintain accurate documentation.

4. Conduct regular audits and inspections.

Continuous Monitoring

1. Regularly review stability data.

2. Conduct root cause analyses (RCAs) for deviations.

3. Implement corrective and preventive actions (CAPAs).

4. Continuously improve manufacturing and storage processes.

By implementing these strategies, pharmaceutical manufacturers can optimize the stability of their products, ensuring patient safety and product efficacy.